| 齒(chǐ)輪箱潤滑油(you)泵采用3gr70*3w21三螺(luó)杆泵配18.5kw-4電機(ji) | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 發布時間:2015-3-5 10:15:36 點(diǎn)擊次數: | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

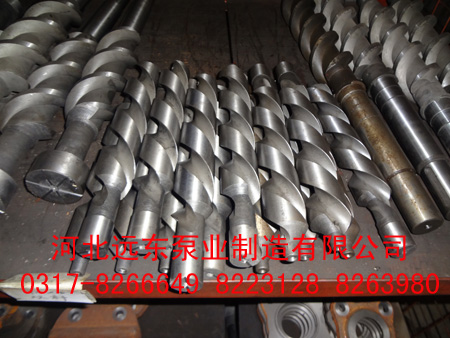

3GR70*3W21三螺(luó)杆泵參數表(biao):

油品的顔色(sè),往往可以反(fǎn)映其精制程(chéng)度和穩定性(xing)。對于💁基🛀🏻礎油(yóu)來說,一般精(jīng)制程度越高(gao),其烴的氧化(huà)物和硫化物(wu)脫除的🥵越幹(gàn)🌈淨,顔色也就(jiu)越淺。但是,即(ji)使精制的條(tiao)件相同,不同(tong)油源🙇🏻和基屬(shǔ)的原油所生(shēng)☁️産的基礎油(yóu),其顔色和透(tou)明度也可能(néng)是不相同的(de)。 對于新的成(chéng)品潤滑油,由(yóu)于添加劑的(de)使用,顔色作(zuo)為判斷基礎(chu)💰油精制程度(dù)高低的指标(biāo)已失去了它(ta)🌈原來的意義(yì)。 密度:密度是(shi)潤滑油最簡(jian)單、最常用的(de)物理性能指(zhi)标。潤滑油的(de)密度随其組(zu)成中含碳、氧(yǎng)、硫的數量的(de)增加而增大(dà),因而在同樣(yàng)📐粘度或同樣(yang)相對分子質(zhi)量的情況下(xia),含芳烴多的(de),含膠質和瀝(lì)♻️青質多的潤(run)滑油密度最(zuì)大,含環烷烴(tīng)多的居中,含(han)烷烴多的最(zui)小。 粘度 粘度(du)反映油品的(de)内摩擦力,是(shi)表示油品油(yóu)性和流動性(xìng)的一項指标(biāo)。在未加任何(hé)功能添加劑(jì)的前提下,粘(zhān)✌️度越大,油膜(mó)強度越高,流(liu)動性越差。 粘(zhān)度指數:粘度(du)指數表示油(yóu)品粘度随溫(wēn)度變化的程(cheng)度。粘度指🙇🏻數(shù)越高,表示油(you)品粘度受溫(wen)度的影響越(yue)小,其粘溫性(xìng)能越好,反🆚之(zhi)越差。 用來輸(shū)送溫度≤150℃、粘度(du)3-760cSt、不含固體顆(kē)粒、無腐蝕性(xìng)、具有潤滑性(xing)能的介質。适(shi)用壓力範圍(wei):0.6-2.5Mpa;适用流量範(fàn)圍:0.6-123m3/h。主要應用(yong)于燃油輸送(song)、液壓工程、船(chuan)舶工程,石化(hua)及🔞其📞他🈚工業(ye)。Used to transfer temperature 150 ℃, the viscosity of 3 or less - 760 CST, not containing solid particles,non-corrosive, has the lubrication performance of the medium.Apply pressure range: 0.6 to 2.5 Mpa;Applicable flow range: 0.6-123 m3 / h.Mainly used in the fuel transfer, hydraulic engineering, Marine engineering, petrochemical and other industries. 應用範圍:1、介(jie)質為直線連(lián)續輸送、無攪(jiao)拌、無脈動。2、振(zhen)動小,噪音低(dī)。3、壓力高、效率(lü)高。4、結構簡單(dan)、拆裝方便。5、體(ti)積小,重量輕(qing)。6、磨損輕微,壽(shòu)命長。Application scope: 1, medium for linear continuous transmission, without stirring, without pulsation.2, small vibration, low noise.3, high pressure and high efficiency.4, simple structure, convenient tear open outfit.5, small volume, light weight.6, wear light, long service life. 3G型三螺(luo)杆泵是轉子(zi)型容積泵,适(shì)于輸送各種(zhǒng)不含❌固體顆(ke)粒,無腐蝕性(xìng)油類及類似(sì)油的潤滑性(xìng)液體✨、輸送液(yè)體粘度2~760mm2/s,溫度(du)不超過80℃, 超過(guo)80℃可用高溫泵(bèng)3GW型。3 g type is three screw pump rotor type positive displacement pump, is suitable for conveying various not containing solid particles, non-corrosive oil lubricity and similar oil liquid, conveying liquid viscosity was 2 to 760 / s, temperature not over 80 ℃, more than 80 ℃ high temperature pump available 3 gw type. 3G型三螺杆(gan)具有多種結(jie)構,一般小流(liu)量泵襯套和(he)泵體合為一(yī)個,可以卧式(shì)和立式安裝(zhuang)。進油口方向(xiàng)可❗相隔90°任意(yi)安裝,軸封多(duo)數為機構密(mì)封。中等流量(liang)以上泵,襯套(tao)為一個單獨(dú)的零件固定(ding)于泵體内,螺(luó)杆軸端裝有(you)平衡環以液(yè)力平衡其軸(zhóu)向力。一般結(jie)構為卧式。進(jìn)油口方向亦(yì)可以相隔90°任(ren)意安裝。改變(biàn)泵體後可制(zhì)成立式。軸封(fēng)根據情況有(you)機械密封和(hé)軟填料密封(feng)兩種結構。Three screw with multiple structure of 3 g, general small flow pump bushings and pump body into one, can be installed in a horizontal and vertical.Oil inlet direction can be 90 ° apart any installation, most of the shaft sealing seal for your organization.The medium flow in pump, bushing as a separate component fixed in the pump body, screw shaft end is equipped with the gimbal ring to hydraulic balance the axial force.The general structure is horizontal.Inlet direction also can be 90 ° apart any installation.After the change of pump body can be made into vertical.Depending on the situation of the shaft sealing with mechanical seal and soft packing seal two structures. 3G型(xíng)三螺杆泵軸(zhou)伸支承較小(xiǎo),應由原動機(ji)經彈性聯軸(zhóu)♊器直接驅動(dong),不得用皮帶(dài)輪等會産生(shēng)額外徑向力(lì)較大的傳動(dòng)🙇♀️方式傳動。3 g type three-screw pump shaft and bearing is small, should be driven by a prime mover directly by the elastic coupling, shall not be used pulley will produce additional radial force large transmission way. 輸(shū)送各種油類(lei)時應注意事(shi)項:When conveying various oil matters should be paid attention to: 1、輸送40~150mm2/s的油(yóu)類最合适,允(yǔn)許按泵的最(zui)高工作壓力(li)使用。2、輸送40mm2/s以(yi)下的油類,為(wei)保證泵的流(liu)量及壽命應(ying)降壓使用。3、輸(shu)送150mm2/s以上的油(yóu)類,且進油管(guǎn)道過長,彎頭(tou)過多,泵工作(zuò)時如産生噪(zao)音或振動現(xiàn)象,則應考慮(lǜ)更換低一級(ji)轉速的💔電機(jī)運轉🤟或縮短(duǎn)吸入管道,減(jiǎn)少彎頭。1, delivery was 40 ~ 150 / s best oils, permitted to use according to the maximum working pressure of pump.2, transmission oil, under 40 was/s in order to ensure the pump flow and life should be used antihypertensive.3, transmission of more than 150 was/s oils, and the oil inlet pipe is too long, too much bend, such as noise or vibration phenomenon when the pump work, should consider to replace the low level of rotational speed of motor operation or shorten the suction pipe, reducing elbow. 3G型三(san)螺杆泵安裝(zhuāng)要求:3 g type three-screw pump installation requirements: 1、安裝前(qian)應檢查泵的(de)油封是否良(liáng)好,并檢查泵(beng)在運❌輸中是(shì)否損壞,可用(yong)手轉動聯軸(zhóu)器是否有卡(ka)勁現象,如有(yǒu)則應拆泵進(jìn)❤️行清洗,修理(li)和校正。2、安裝(zhuang)泵的進油和(hé)排油管道時(shí),其管徑不得(dé)小于泵的🔱進(jìn)油和出👌油口(kǒu)口徑,進油管(guǎn)道不得過長(zhang),彎頭不得過(guò)多,否則将影(yǐng)響泵的工作(zuo)狀态。3、當有兩(liang)台以上的泵(beng)安裝在同一(yī)條主管線上(shàng),為便于泵的(de)🐕啟動,在近泵(beng)的排油管上(shang)必須安裝逆(nì)止閥。4、對于在(zài)較高溫度(指(zhi)60℃以上)下輸送(sòng)粘度大的油(yóu)類(如:重油)的(de)備用泵,必須(xū)是熱🥰備用泵(beng)😘,否則泵在低(dī)溫下啟動會(huì)造成電機過(guò)載或泵損壞(huai)。(建議在靠近(jìn)泵的排油管(guǎn)上的逆止閥(fa)旁,并聯安裝(zhuang)一個小回流(liu)閥,對備用泵(beng)可微啟回流(liú)閥,使泵緩💋慢(man)逆轉,其逆轉(zhuǎn)速≤100轉/分,使部(bu)分熱油經常(cháng)流過泵内,達(da)到泵熱備用(yòng)目的)。5、輸送介(jiè)質内含有機(jī)械雜質。将嚴(yán)重影響泵的(de)運轉🎯和降🈲低(di)👉使用壽命,因(yīn)此在泵安裝(zhuang)前,必須仔細(xì)清除進油管(guan)内的焊渣,沙(sha)粒等雜質,并(bìng)應在進油管(guan)道靠近泵處(chu)安裝濾器,濾(lǜ)器網孔大小(xiǎo),可根據工作(zuo)情況㊙️及介質(zhi)粘🈲度确定。(一(yi)般可用40~80目網(wang)),過濾面積一(yi)般不得小于(yu)進油管橫截(jie)面積的20倍。6、盡(jìn)量在泵進油(you)和排油口處(chu)的螺紋孔上(shang)連接壓力表(biao)🙇♀️和✨真🐉空表,以(yi)便于觀察泵(bèng)的運轉狀态(tài)。7、原動機與泵(beng)的轉軸必須(xū)在同一中心(xin)線上,可用直(zhí)尺測隙規在(zai)🐇聯軸器圓周(zhōu)上間隔90°處檢(jian)查。8、原動機與(yu)泵的轉向必(bì)須一緻,嚴格(gé)禁止原動機(ji)驅動泵逆轉(zhuan)。電🧑🏾🤝🧑🏼機接線時(shí),應先脫開電(dian)機與泵的聯(lian)軸器,對電機(jī)作試運轉。使(shǐ)其轉向與泵(bèng)的轉向标志(zhì)一緻。1, before installation should check whether the oil seal of the pump is good, and check the pump is damaged in transportation, turn the coupling usable hand card trouble phenomenon, if there is any should tear open pump for cleaning, repair and calibration.2, installation of pump suction and discharge of oil pipe, the pipe diameter shall not be less than the oil inlet of the pump and the oil outlet diameter, inlet pipe shall not be too long, elbow shall not too much, otherwise will affect the pump working condition.3, when more than two head of pump installed in the same line, to facilitate pump start-up, in close to the oil drain pump must be installed on a non-return valve.4, for under high temperature (above 60 ℃) conveying the viscosity of oil (such as: heavy oil) of the standby pump, it must be hot standby pump, otherwise the pump at low temperature can cause the damage of motor overload or pump.(suggest near the exhaust non-return valve on the tubing pump, a small return valve installed in parallel, differentiable and the backflow preventer to standby pump, the pump slow reversal, the reverse speed 100 r/min or less, often make some hot oil flows through the pump, to pump hot standby purposes).5, mechanical impurity is contained within the transmission medium.Will seriously affect the operation and reduce the service life of pump, so before the pump installation, must be carefully clean up the feed tube welding slag, impurities such as grains of sand, and shall be installed in the inlet pipe near the pump filter, filter mesh size, is decided according to the working condition and medium viscosity.Available (40 ~ 80 mesh net), filter area generally shall not be less than 20 times into the cross-sectional area of the tubing.6, as far as possible in the pump suction and discharge of oil on the threaded hole mouth connect pressure gauge and vacuum gauge, in order to observe the pump running state.7, prime mover and the pump shaft must be in the same center line, available ruler feeler gauge in the coupling of the circumference of a circle by 90 ° in check.8, steering engine and pump must be consistent, strictly prohibited prime motor driven pump reversal.Electrical wiring, should first release coupling of motor and pump, a test run on the motor.The steering pump and steering sign agreement. 3G型三螺(luó)杆泵的使用(yòng)1、泵啟動前,必(bì)須全開進油(yóu)和排油閘閥(fa)。2、首次啟動泵(beng)或再次使用(yòng)長期封存的(de)泵時,泵内無(wu)介質,應🚶♀️在泵(beng)的進油腔灌(guàn)注适量輸送(sòng)介質,避免泵(beng)幹啟動。3、泵啟(qǐ)動後,應密切(qiē)注意電流表(biǎo),壓力表和真(zhēn)空表的數值(zhí),超出規定值(zhí)時,應停泵找(zhǎo)出原因後,再(zai)行啟動。4、軸封(feng)處點滴洩露(lu),應屬正常現(xian)象,當洩露量(liang)大量增加🆚時(shi)👨❤️👨,對軟填料密(mi)封應壓緊填(tian)料壓蓋,對機(ji)械密封應停(ting)✌️泵修複後,再(zai)行啟動。5、用高(gāo)溫蒸汽清掃(sao)管線時,應避(bì)免高溫蒸汽(qi)通過泵内。6、如(rú)果泵長期不(bu)工作時,應進(jin)行油封,并定(dìng)期檢查油🈲封(feng)😍情況,必要時(shi)重新油封。The use of 3 g type three-screw pump 1, before starting the pump, oil inlet must be fully open and oil discharge gate valve.2, start the pump for the first time or again for a long time use of the pump, the pump inside without medium, should be in the inlet of the pump cavity perfusion amount transfer medium, avoid dry start pump.3, the pump starts, should pay close attention to current meter, pressure gauge and vacuum gauge value, beyond the specified value, should stop pump after find out, start again.4, shaft sealing drip leakage, should belong to the normal phenomenon, when the leak amount of increase, the soft packing seal should be compression packing gland, to pump mechanical seal shall be shutdown after repair, start again.5, with high temperature steam cleaning pipeline, should avoid high temperature steam through the pump.6, if the pump is not working for a long time, should carry on the oil seal, and regularly check oil seal, oil seal again if necessary.

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 地(dì)址: | 河北省泊(bó)頭市道女性❌人体写真㊙️東街(jiē)88号 |

| 電話: | 0317-8185077 |

| 0317-8263980 | |

| 0317-8223128 | |

| 傳真(zhēn): | 0317-8265584 |

| E-mail: | [email protected] |

潤滑油一般(ban)由基礎油和(he)添加劑兩部(bù)分組成。基礎(chǔ)♋油是潤滑油(you)的主要成分(fen),決定着潤滑(hua)油的基本性(xing)質,添加劑則(ze)可📐彌補和改(gai)善基礎油性(xìng)能方面的不(bú)足,賦予某些(xie)新💃的性能,是(shi)潤滑油的重(zhòng)要組成部分(fen)。

潤滑油一般(ban)由基礎油和(he)添加劑兩部(bù)分組成。基礎(chǔ)♋油是潤滑油(you)的主要成分(fen),決定着潤滑(hua)油的基本性(xing)質,添加劑則(ze)可📐彌補和改(gai)善基礎油性(xìng)能方面的不(bú)足,賦予某些(xie)新💃的性能,是(shi)潤滑油的重(zhòng)要組成部分(fen)。